Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Brass Pex Connect Fittings, Manifold Brass Stainless Steel Water Diversity Set, Brass Float Valve, We always welcome new and old customers presents us with valuable advice and proposals for cooperation, let us grow and develop together, and to contribute to our community and staff!

Short Lead Time for Brass Bleeder Valve - BALL VALVES-S5082 – Shangyi Detail:

Key words: Brass Ball Valves, Forged Brass Ball Valves, Nickel-plated Brass Ball Valves, Brass Valves, Ball Valves, Valves

Product information :

| Product name |

BALL VALVES |

| Sizes |

1″1/2″3/4″ |

| Bore |

Full bore |

| Application |

Water and other non-corrosive liquid |

| Working pressure |

PN16 |

| Working temperature |

-10 to 110°C |

| Quality standard |

EN13828, EN228-1/ ISO5208 |

| End Connection |

BSP |

| Features: |

Heavy-duty design for higher pressure |

| Anti-blow-out stem structure/O-Ring or Pressure Nut |

| 100% leakage test on valve before delivery |

| Agents wanted and OEM acceptable |

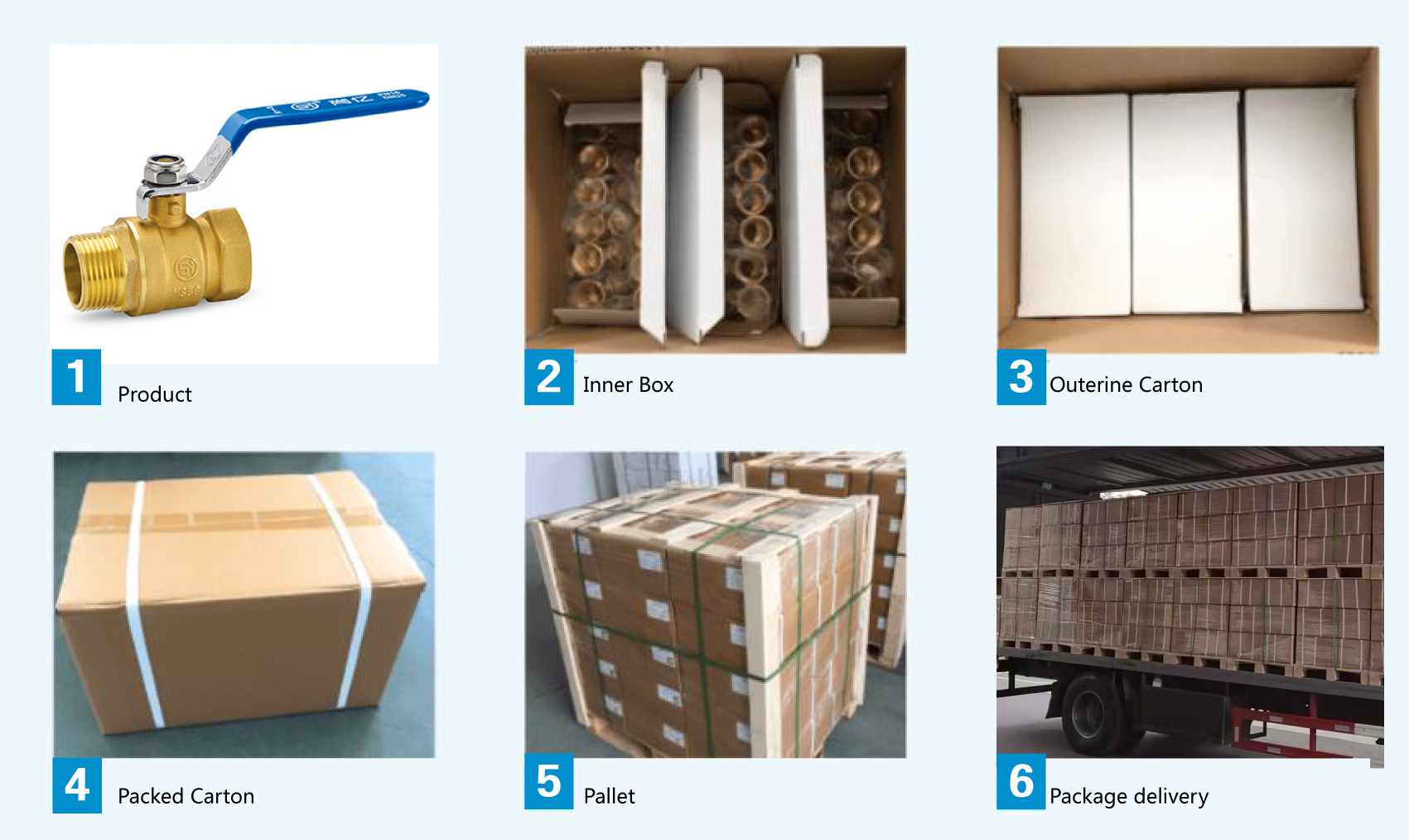

| Packing |

Inner boxes in cartons, loaded in pallets |

| Customized design acceptable |

Spare Part for brass ball valves:

| NO |

Component |

Material |

| 1 |

Body |

Brass |

| 2 |

Bonnet |

Brass |

| 3 |

Ball |

Brass |

| 4 |

Seat |

PTFE |

| 5 |

O-ring |

EPDM |

| 6 |

NUTS |

Brass |

| 7 |

Hot melt |

PPR |

| 8 |

O-ring |

NBR |

| 9 |

Stem |

Brass |

| 10 |

Handle |

Steel |

| 11 |

Nut |

Steel |

Bore sizes for brass ball valves:

| SIZE |

L |

H |

DN |

D |

Weight |

Carton |

| 20×20 |

85 |

45 |

14.8 |

98 |

285 |

72 |

| 25×25 |

100 |

46 |

19 |

98 |

368 |

48 |

| 32×32 |

112 |

50 |

24 |

122 |

565 |

36 |

| 40×40 |

123.5 |

68.5 |

37 |

138 |

950 |

12 |

| 50×50 |

131.5 |

69.5 |

32 |

138 |

1220 |

12 |

| 63×63 |

155 |

75.5 |

40 |

176 |

1970 |

12 |

| 75×75 |

173 |

95.5 |

50 |

155 |

3235 |

8 |

| 90×90 |

203 |

111.5 |

62 |

220 |

5050 |

4 |

Production flow of Brass Ball Valves :

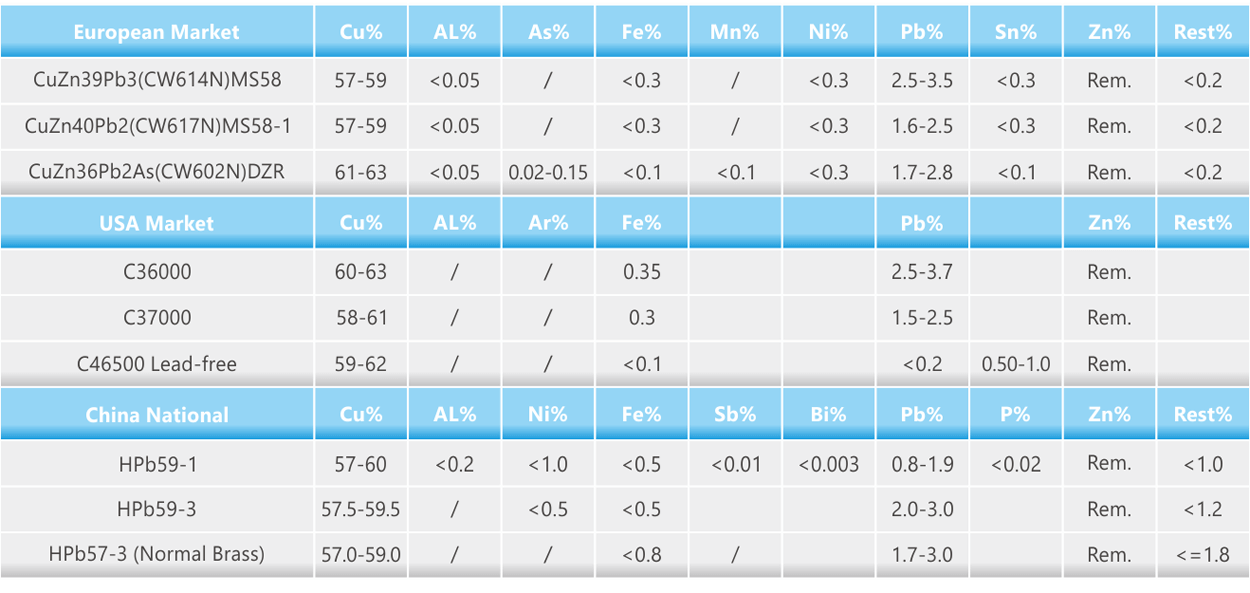

Brass material Chemical composition used for brass ball valves:

Available surface treatments of brass ball valves:

Packing of brass ball valves:

Testing Lab for brass ball valves:

Why choose SHANGYI as your China valves supplier:

1.rofessional valve manufacturer,with over 20 years of industry experiences.

2.Monthly production capacity of 1million sets,enables quick delivery

3.Testing each valve one by one

4.Intensive QC and on-time delivery,to make quality reliable and stable

5.Prompt responsive communications,from pre-sales to after-sales

Product detail pictures:

Related Product Guide:

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for Short Lead Time for Brass Bleeder Valve - BALL VALVES-S5082 – Shangyi , The product will supply to all over the world, such as: Stuttgart, Yemen, Palestine, We have to continue to uphold the "quality, comprehensive, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.