The installaton is very important for the function of brass ball valves, improper installation may cause damage to the valves and misfunction of the fluid control system, Here is the instruction for Brass Ball Valve Installation.

General Guidelines

♦ Ensure that the valves to be used are appropriate for the conditions of the installation (the type of fluid, pressure and temperature).

♦ Be sure to have enough valves to be able to isolate the sections of piping as well as the appropriate equipment for maintenance and repair.

♦ Ensure that the valves to be installed are of correct strength to be able to support the capacity of their usage.

♦ Installation of all circuits should ensure that their function can be automatically tested on a regular basis (at least two times a year).

Brass Ball Valve FF installation

Brass Ball Valve FM installation

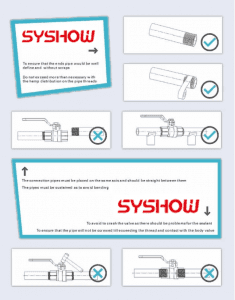

♦ Before installing the valves, clean and remove any objects from the pipes (in particular bits of sealing and metal), which could obstruct and block the valves.

♦ Ensure that both connecting pipes either side of the valve (upstream and downstream) are aligned (if they are not the valves may not work correctly).

♦ Make sure that the two sections of the pipe (upstream and downstream) match, the valve unit will not absorb any gaps. Any distortions in the pipes may affect the tightness of the connection, the working of the valve and can even cause a rupture.

♦ To be sure, place the kit in position to ensure the assembling will work.

♦ Before starting the fitting, ensure that the threads and tapping are clean.

♦ If sections of piping do not have their final support in place, they should be temporarily fixed. This is to avoid unnecessary strain on the valve.

♦ The theoretical lengths given by ISO/R7 for the tapping are typically longer than required, the length of the thread should be limited, use PTFE tape to ensure the tightness of the fixing, and check that the end of the tube does not press right up to the head of the thread.

♦ Position the pipe clips on both sides of the valve.

♦ If mounting on an air conditioning with PER tubing and hoses, it is necessary to support the tubes and hoses with the fixing to avoid strain on the valve.

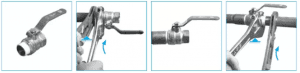

♦ When screwing the valve, ensure that you only rotate on screwed side by the 6 ended side. Use an open ended spanner or an adjustable spanner and not a monkey wrench.

♦ Never use a vice to tighten the fixings of the valve.

♦ Do not over tighten the valve. Do not block with any extensions as it may cause a rupture or weakening of the casing.

♦ In general, for all valves used in buildings and heating, do not tighten above a torque of 30 Nm

The advice and assembly instructions above do not conform to any guarantee. The information is given in general. It states what must not and must be done. It is provided to ensure the safety of the personnel and the reliability of the valves. The instructions in bold must be followed.

Post time: Mar-26-2020